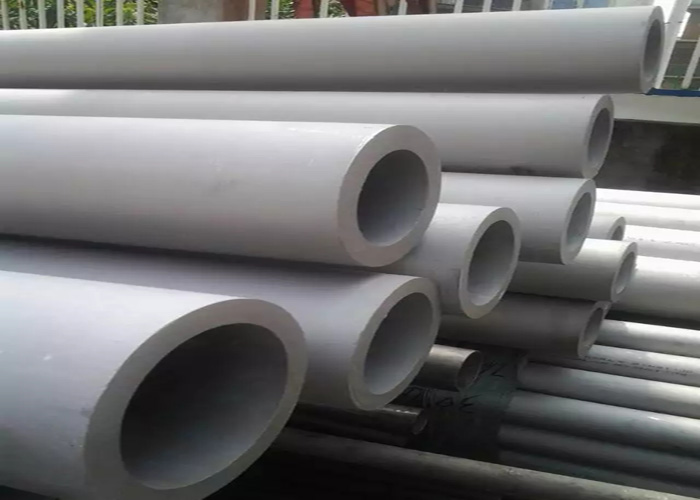

What are the heavy wall stainless steel tubing sizes?

Heavy wall stainless steel tubing are usually divided into stainless steel thin-walled pipes. Generally, stainless steel thick-walled pipe steel pipes have a wall thickness greater than 10 mm, or SCHW, SCHXS, SCH160, SCHXXS, etc., and the steel pipes are seamless and There are two types of welded steel pipes.

According to the different manufacturing processes, it can be divided into hot rolling, hot rolling, cold drawing, etc. According to the sectional shape, it can be divided into round tubes and heterogeneous tubes. Most of the industries are round steel tubes, but there are also some squares. , rectangular, hexagonal, etc. stainless steel tubes. For stainless steel pipes subjected to a certain pressure, hydraulic tests are carried out to check the pressure resistance and quality. No leakage occurs under the specified pressure, and the expansion is qualified overclocking. Some steel pipes are also required to be rolled according to their standards or the requirements of the purchaser. Side test, flare test, flattening test, hardness test, etc. Generally speaking, the thicker the wall thickness of the steel pipe, the greater the pressure that can be withstood, and the safer the use. It is only relatively expensive. Stainless steel thick-walled tubes are divided into seamless and seamed. Seamless stainless steel tubes are also called stainless steel seamless tubes. They are made of steel ingots or solid tube blanks, which are then made by hot rolling, cold rolling or cold drawing. The specifications of the seamless steel pipe are expressed by the outer diameter × wall thickness mm number.

For example, what are the dimensions of heavy wall stainless steel tubing?

Heavy wall stainless steel tubing 321 273*7*6.68

Heavy wall stainless steel tubing 321 219*21*1260

Heavy wall stainless steel tubing 321 219*14*1000

Heavy wall stainless steel tubing 321 219*11*1650

Heavy wall stainless steel tubing 321 114*20*5.5

Heavy wall stainless steel tubing 321 114*20*3.12

Heavy wall stainless steel tubing 321 105*3*1160

Heavy wall stainless steel tubing TP321 813*22

Heavy wall stainless steel tubing TP321 711*33

Heavy wall stainless steel tubing TP321 660*58*1.1

Heavy wall stainless steel tubing TP321 610*45

What are the heavy wall stainless steel tubing sizes?

| DNmm | DNin | φmm | Sch60 | Sch80s | XS | Sch80 | Sch120 |

| 6 | 1/8 | 10.3 | 2.41 | 2.41 | 2.41 | ||

| 8 | 1/4 | 13.7 | 3.02 | 3.02 | 3.02 | ||

| 10 | 3/8 | 17.1 | 3.2 | 3.2 | 3.2 | ||

| 15 | 1/2 | 21.3 | 3.73 | 3.73 | 3.73 | ||

| 20 | 3/4 | 26.7 | 3.91 | 3.91 | 3.91 | ||

| 25 | 1 | 33.4 | 4.55 | 4.55 | 4.55 | ||

| 32 | 1 1/4 | 42.2 | 4.85 | 4.85 | 4.85 | ||

| 40 | 1 1/2 | 48.3 | 5.08 | 5.08 | 5.08 | ||

| 50 | 2 | 60.3 | 5.54 | 5.54 | 5.54 | ||

| 65 | 2 1/2 | 76 | 7.01 | 7.01 | 7.01 | ||

| 80 | 3 | 88.9 | 7.62 | 7.62 | 7.62 | ||

| 90 | 3 1/2 | 101.6 | 8.08 | 8.08 | 8.08 | ||

| 100 | 4 | 114.3 | 8.56 | 8.56 | 8.56 | 11.13 | |

| 125 | 5 | 141.3 | 9.53 | 9.53 | 9.53 | 12.7 | |

| 150 | 6 | 168.3 | 10.97 | 10.97 | 10.97 | 14.27 | |

| 200 | 8 | 219.1 | 10.31 | 12.7 | 12.7 | 12.7 | 18.26 |

| 250 | 10 | 273 | 12.7 | 12.7 | 12.7 | 15.09 | 21.44 |

| 300 | 12 | 323.8 | 14.27 | 12.7 | 12.7 | 17.48 | 25.4 |

| 350 | 14 | 355.6 | 15.09 | 12.7 | 19.05 | 27.79 | |

| 400 | 16 | 406.4 | 16.66 | 12.7 | 21.44 | 30.96 | |

| 450 | 18 | 457 | 19.05 | 12.7 | 23.83 | 34.93 | |

| 500 | 20 | 508 | 20.62 | 12.7 | 26.19 | 38.1 | |

| 550 | 22 | 559 | 22.23 | 12.7 | 28.58 | 41.28 | |

| 600 | 24 | 610 | 24.61 | 12.7 | 30.96 | 46.02 |

Brief description of the production process of heavy wall stainless steel tubing:

1. Waste pipe (tube blank):

The raw material for the stainless steel round billet used in the production is called a waste pipe.

2, cut the tube:

When producing stainless steel thick-walled pipes, the head and tail should be cut off, including the cutting of the two ends of the waste pipe, the cutting of the intermediate products and the cutting of the finished product. Steel pipe scrap is produced when the steel pipe is cut.

3, pickling, degreasing:

The surface of the stainless steel thick-walled tube is removed by high-temperature heating, so as to meet the requirements of the production of steel pipes and finished products. The engineering acid is a mixed acid (HNO3 + HF).

4, inspection and grinding:

Inspect and repair the defects of stainless steel thick-walled tubes to remove unfavorable defects.

5, cold drawing (rolling):

The steel pipe is deformed to the required specifications, and the steel pipes of different specifications are subjected to acid washing and solution treatment in multiple passes.

6, solid solution:

The stainless steel thick-walled tube undergoes metal work hardening after cold drawing (rolling). In order to eliminate work hardening and facilitate reprocessing, the solidified film is used to recover the broken crystal grains. At the same time, it also guarantees the mechanical properties of the finished steel pipe.

7, straightening:

The steel pipe after solid solution (annealing) is bent due to thermal deformation, and the steel pipe is straightened to meet the straightness standard of the steel pipe.

8. Lubrication:

Before the cold drawing process, the steel pipe does not directly generate friction between the steel pipe metal and the extruding die metal during the deformation process. Therefore, the inner and outer surfaces of the steel pipe are coated with a lubricant prepared by high-temperature nano-base grease + lime. To form a layer of isolation

So, how do you choose a manufacturer of heavy wall stainless steel tubing?

There are hundreds of thousands of stainless steel seamless pipes in China, but there are not many manufacturers that can produce heavy wall stainless steel tubing. Some manufacturers, despite producing stainless steel thick-walled pipes, often have very common quality and are suitable for general use. The basic industry does not require high quality, but some thick-walled pipes are used in pressure vessels and special equipment, which requires very strict quality requirements. Zheheng steel has been engaged in the import and export of stainless steel pipes for many years. The products are mainly sold to European and American markets, and our company also has more than 300 tons of stainless steel thick-wall pipe exports every year.

Previous: >> New Client Taiwan – E United Group for stainless steel pipe fittings Next: >> India end user inquiry to us for Stainless Steel Seamless Pipes