Tempering effect of stainless steel pipe

Work hardening due to cold working means that the subsequent forming process is tempered. Therefore, tempering has a direct impact on the molding process and cost. It is well known that when a metal deforms near or below room temperature, hardening occurs, which increases the strength and hardness of the metal material.

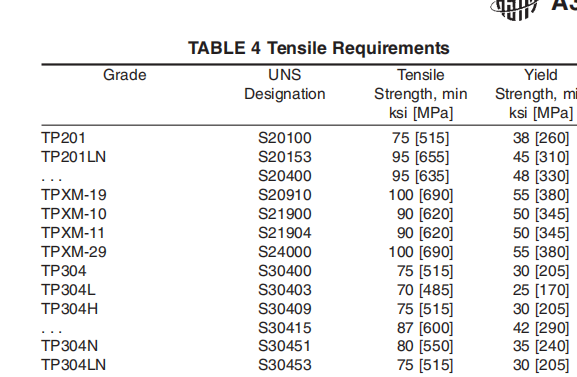

In fact, not all stainless steel pipes can be subjected to the desired forming process. For example, the ferritic 400 series stainless steel tube can only have a small amount of deformation during cold working, otherwise sudden damage or cracking will occur. For example, the 430 and 446 stainless steel tubes have gap sensitivity, so their supply status should be annealed. When they must be shaped, they must be tempered. Hardened martensitic steels are also supplied in an annealed condition, otherwise these steels are either normalized or cured, or delivered in a quenched and cured state. However, austenitic stainless steel tubes are available in a wide range of cold working hardnesses. The subscripts list the mechanical properties associated with various tempering of austenitic 300 series stainless steel tubes. Not all austenitic stainless steel tubes of all sizes and steel grades can be formed after tempering. Steels such as 201, 202, 301, 302, and 304 with less alloy content are very suitable for cold drawing; for steels with high alloy content and low cold work hardening rate, they are not widely used for production of more than 1/2 cold work. A tempered product in a hardened state. Steels 305, 316, 317 and 310 belong to the latter category. As the nickel content increases, the tendency to work harden is reduced.

It should be mentioned that some non-standard chromium-manganese austenitic stainless steel pipes significantly expand the processing range of cold drawn steel pipes. The tempering-size relationship diagram of a large-sized stainless steel pipe by cold drawing into a small-diameter stainless steel pipe may be slightly changed when the small-sized steel pipe is processed and produced. When producing small-sized stainless steel pipes larger than the annealing hardness, especially when it is desired to have 1/2 chilling property, equipment for producing small-sized stainless steel pipes should be considered.

Due to the utilization rate of raw materials, the rate of achievement is a necessary condition, and all of the above basic knowledge is expected to contribute to the improvement of the yield of stainless steel pipes. When processing cold drawn steel pipes, the restrictions on the production of stainless steel pipes must be considered. Due to price constraints, lubricant performance and the inherent factors of the above analysis, only certain sizes of stainless steel tubing can be cold drawn in various tempered conditions.

Previous: >> Why does the stainless steel pipe rust and corrode? Next: >> Stainless steel tube tensile strength and yield strength