Stainless Steel Pipe Fittings: Strength For Modern Piping Systems

In the world of industrial and commercial piping, reliability is everything. Whether it’s a chemical plant, a food processing facility, or a residential plumbing system, the components used must withstand pressure, corrosion, and time. Among the most trusted materials in piping systems today are stainless steel pipe fittings—valued for their unmatched durability, corrosion resistance, and adaptability across a wide range of applications.

In the world of industrial and commercial piping, reliability is everything. Whether it’s a chemical plant, a food processing facility, or a residential plumbing system, the components used must withstand pressure, corrosion, and time. Among the most trusted materials in piping systems today are stainless steel pipe fittings—valued for their unmatched durability, corrosion resistance, and adaptability across a wide range of applications.

What Are Stainless Steel Pipe Fittings?

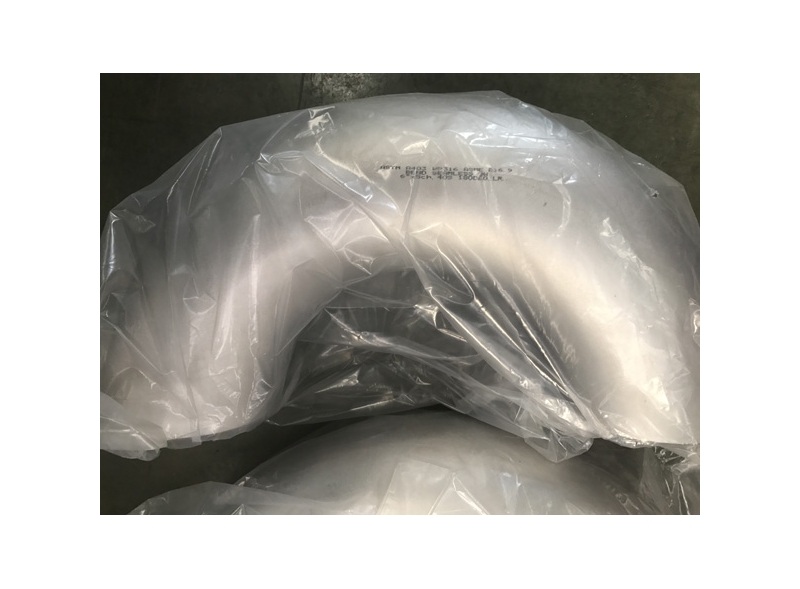

Stainless steel pipe fittings are components used to connect, control, or change the direction of pipes in a piping system. Made from high-grade stainless steel alloys such as 304 or 316, these fittings are built to resist corrosion, high temperatures, and mechanical stress. They come in various shapes and sizes, including elbows, tees, reducers, couplings, caps, and flanges.

Their primary role is to ensure leak-proof connections and maintain the integrity of the flow within the system—whether it's transporting water, gas, oil, chemicals, or food-grade substances.

Why Choose Stainless Steel Pipe Fittings?

1.Corrosion Resistance

Stainless steel is naturally resistant to rust and corrosion, especially alloys like 316 which contain molybdenum for added protection against chlorides and harsh chemicals. This makes stainless steel fittings ideal for marine environments, chemical processing, and water treatment plants.

2.High Strength and Durability

Stainless steel maintains its strength and structural integrity under high pressures and temperatures. It doesn't deform or degrade easily, ensuring a long service life even in demanding environments.

3.Hygienic and Easy to Clean

Thanks to its smooth, non-porous surface, stainless steel is easy to clean and sterilize, making it the preferred material for food and beverage processing, pharmaceutical, and medical applications.

4.Versatility

Stainless steel pipe fittings are compatible with a wide range of piping materials and fluids. They are available in threaded, welded, and socket-welded forms to suit various system requirements.

5.Aesthetic Appeal

For exposed piping systems, stainless steel offers a clean, modern appearance that’s both functional and visually appealing.

Common Applications of Stainless Steel Pipe Fittings

●Industrial Piping Systems: Used in refineries, chemical plants, and power stations for transporting steam, gas, and liquids.

●Food and Beverage Industry: For sanitary piping systems requiring sterile conditions and ease of cleaning.

●Pharmaceutical and Medical Facilities: Stainless steel fittings meet strict hygiene standards and resist contamination.

●Construction and Architecture: Used in water supply lines, fire protection systems, and HVAC applications.

●Oil and Gas: Ideal for high-pressure and corrosive environments where safety and reliability are paramount.

Types of Stainless Steel Pipe Fittings

●Elbows (45° and 90°): Change the direction of the piping.

●Tees and Crosses: Distribute fluid into multiple directions.

●Reducers: Connect pipes of different diameters.

●Couplings and Unions: Join two pipes together.

●Flanges: Provide easy disassembly and connection of piping sections.

Conclusion

Stainless steel pipe fittings are essential for building long-lasting, high-performance piping systems. Their strength, resistance to corrosion, and adaptability make them the go-to choice across industries. Whether you’re designing a small plumbing system or a massive industrial installation, choosing stainless steel ensures durability, safety, and peace of mind.

Previous: >> The Backbone of Industry: Why Choose a Specialized Stainless Steel Pipe Supplier Next: >> Polished Stainless Steel Tubing | Precision, Durability And Style