How to produce stainless steel seamless pipes in vernacular?

An old salesman who has been mixed for more than ten years summed up how to produce stainless steel seamless pipes in vernacular?

The first contact with the stainless steel seamless pipe was ten years ago. At that time, I was just introduced by the classmates to sell this thing. Just arrived at the factory and everything else is new, and I have a problem with the stainless steel seamless pipe. When I have a lot, I like to call stainless steel pipes or steel pipes. stainless? Isn't it only the spoon used at home that doesn't rust? A steel pipe has to be made into a stainless steel pipe that does not rust. This is the most common problem at first.

As the name suggests, stainless steel seamless pipes are steel pipes or pipes that do not rust. The so-called pipes are used to circulate water, oil, and gas media. In official terms, stainless steel pipe is a hollow strip of round steel, which is widely used in petroleum, chemical, medical, food, light industry, mechanical instrumentation and other industrial pipelines and mechanical structural components. In addition, when the bending and torsional strength are the same, the weight is light, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also often used as a living area for furniture and kitchenware. Since the deepest contact with me is the industrial grade stainless steel seamless pipe, I am more about introducing this aspect of industry.

The stainless steel pipe is said to be a steel pipe or a pipe. When it is small, it can be divided into a seamless pipe and a seamed pipe (welded steel pipe). Here, the seamless stainless steel pipe is introduced, and the seam is referred to as a seamless concept. After we have literally understood the stainless steel tube, we will first discuss his production process and application field today.

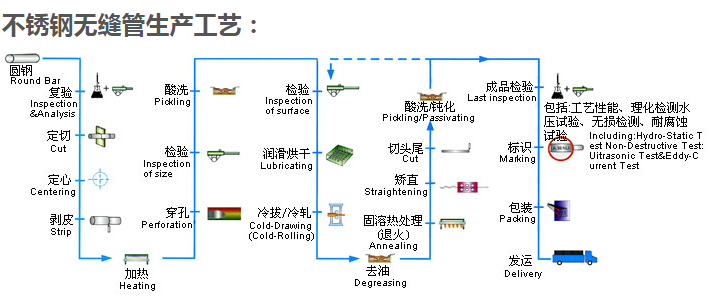

First, the manufacturing process

Mainly divided into cold drawing and cold rolling two processes, cold rolling process is the most mature process in recent years, the production speed is fast, time saving, labor saving, high production efficiency, compared with the cold drawing process (more used in previous years) Equipment) has gradually been replaced,

Advantages of cold rolled tube: a. High yield of finished product, b. Short cycle, c. uniform wall thickness;

Cold rolled tube shortcomings: a. high investment cost, b. mechanical performance is not as cold as drawing tube, c, production range (group distance) is limited (25mm-219mm).

Advantages of cold drawn tube: a. The investment cost is relatively small, b. The production range (group distance) is wide (6-720mm), c. The mechanical performance is due to the cold-rolled tube (favorable for post-processing (bending, U-shaped tube.. .);

Cold tube weakness: a. slow production cycle, low finished product, b. high cost later (manual, natural gas / coal, lubricating lime, equipment consumption..., c, wall thickness is not very uniform (somewhat eccentric)

Cold drawn (rolled) seamless steel pipe: round billet → heating → perforation → head → annealing → pickling → oiling (copper plating) → multi-pass cold drawing (cold rolling) → blank tube → heat treatment → straightening → water Pressure test (inspection) → mark → storage. This program may not be clear to many people.

Chu specific process, the following figure can be used for a simple reference.

The stainless steel seamless pipe production process is briefly described in the form of text:

1. raw material pipe (tube blank):

The raw material of the stainless steel round billet used in the production is called a waste pipe. This is the raw material tube blank that we often say. The color is generally black.

2, cut the tube:

When the stainless steel pipe is produced, the head and tail should be cut off, including the cutting of the two ends of the waste pipe, the cutting of the intermediate product and the cutting of the finished product. Steel pipe scrap is produced when the steel pipe is cut. This is also the loss of steel pipe in the production process, which directly affects the rate of success.

3, pickling, degreasing:

The scale of the stainless steel tube surface is removed by high temperature heating to meet the requirements of the production of steel pipes and the requirements of finished products. The engineering acid is a mixed acid (HNO3 + HF). After the tube blank is produced, because the surface is black, the color can only be removed by soaking in a special proportion of acidic liquid.

4, inspection and grinding:

Inspect and repair the defects of the stainless steel seamless steel pipe to remove the unfavorable defects.

5, cold drawing (rolling):

The steel pipe is deformed to the required specifications, and the steel pipes of different specifications are subjected to acid washing and solution treatment in multiple passes.

6, solid solution:

The stainless steel seamless pipe undergoes metal work hardening after cold drawing (rolling). In order to eliminate work hardening and facilitate reprocessing, the solidified film is used to recover the broken crystal grains. At the same time, it also guarantees the mechanical properties of the finished steel pipe. It is very important about this, why? Nowadays, due to fierce competition, the price of products is getting lower and lower. Some unscrupulous manufacturers have begun to cut corners to reduce the cost of sales to the process, but why do they not see customers? First, customers are not people. The professional and the equipment area test, and the naked eye can not see. In addition, some customers are taking risks, the salesperson is not responsible, not professional, and the eagerness to take orders is doomed to the products that you have obtained. But why didn't the customer have a big problem after buying it? In fact, it is very simple. The environment for many product applications is not complicated. For a long time, it is a simple water-passing ventilation after welding. The requirements for the product itself are not high, and some products can be used for the longest reach of the customer after the product is purchased. Three years, think about it for a long time, and several people still remember the previous product problems.

7, straightening:

The steel pipe after solid solution (annealing) is bent due to thermal deformation, and the steel pipe is straightened to meet the straightness standard of the steel pipe. Many customers have requirements for product straightness and can be solved not only with straightening machines.

8. Lubrication:

Before the cold drawing process, the steel pipe does not directly generate friction between the steel pipe metal and the extruding die metal during the deformation process, so the inner and outer surfaces of the steel pipe are coated with a lubricant prepared by high-temperature nano-base grease + lime. To form a layer of isolation. As the name implies, the friction coefficient of the process is reduced.

Second, the field of application.

Stainless steel seamless pipe is mainly used in industrial transportation pipelines such as petroleum, chemical, medical, food, light industry, mechanical instrumentation, mechanical structural components, etc.

In petroleum, in petroleum and petrochemical, stainless steel pipes are mainly used in pipeline transportation systems, including high-pressure furnace pipes, piping, petroleum cracking pipes, fluid conveying pipes, and heat exchange pipes. Stainless steel is required to perform well in wet and acid service conditions. Oil pipelines are the bulk of stainless steel pipes. Stainless steel pipes play an important role in equipment manufacturing, oil recovery, oil refining and transportation in the petroleum industry. In recent years, the country has increased the development of petroleum resources. At the same time, as the world's largest net oil importing country, with the increasing demand for petroleum, the petroleum-related industries will further develop and the demand for stainless steel pipes will continue. increase.

The most visible in medical care is the establishment of medical equipment and pharmaceutical factories. Pipe material fittings required for various mechanical equipment.

Zheheng Steel not only provides customers with high-quality stainless steel seamless pipes, but also provides customers with solutions in practical applications.

Previous: >> Cold-rolled stainless steel seamless pipe HS cod 7304419000 Next: >> The rise and fall of the price of stainless steel seamless pipe in recent years